Our customers expect short delivery times, stable prices, a high quality level and consistent product innovations from us.

We fundamentally endeavour to have long-term, trusting business relationships with our suppliers with the aim of continuously improving the services and processes in close collaboration. The task of the Purchasing department is the securing of supplies as and when they are needed for all required goods and services at an optimal price performance ratio in order to guarantee an uninterrupted production flow.

We invite you, as an innovative supplier, to take on this challenge together with us. You can obtain information here on our procurement programme, our requirements and the organisation of the Purchasing department of the STP Group.

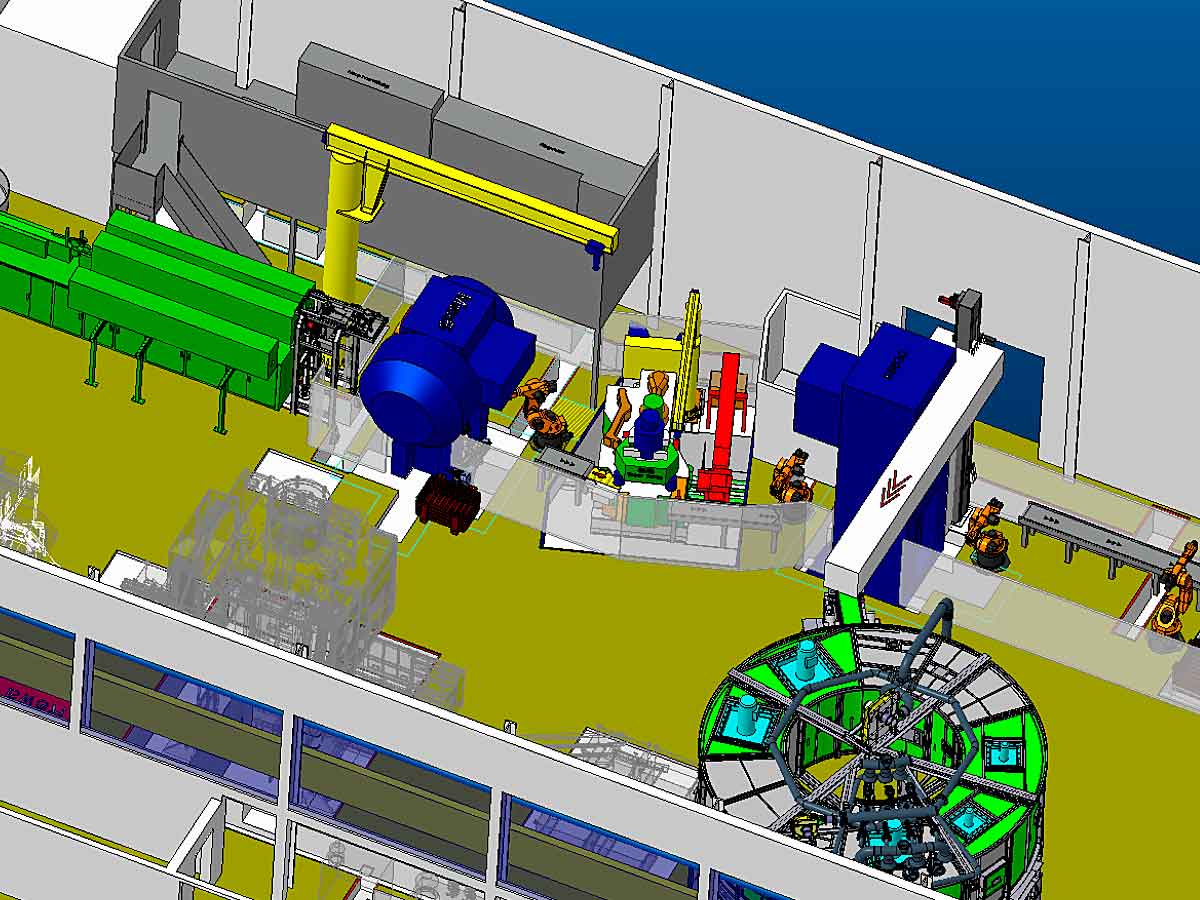

Procurement programme

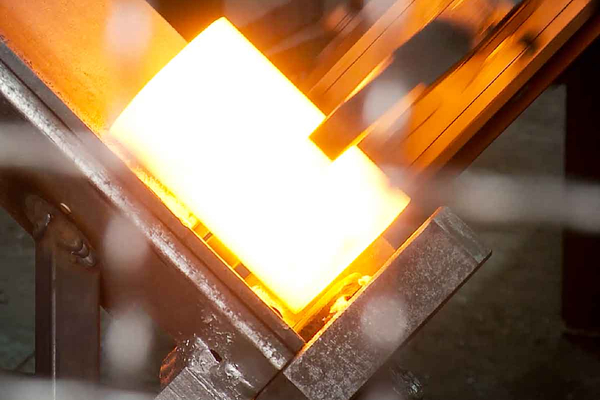

- Raw materials (high-grade steel bars, tool steel, forged parts)

- Technical purchasing (investments, maintenance)

- General purchasing (auxiliary and operating materials, services)

- External machining of forged parts (mechanical processing, heat treatment)

- Trading goods

Purchasing volume

- Total purchase volume > 80 m €

- Investment volume > 11 m €

- Steel purchasing volume approx. 60,000 t

Requirements: You should fulfil the following conditions in order to become an STP supplier:

- Certification to DIN EN ISO 9001/IATF 16949

- Flexibility in your capacities

- Tried and tested quality processes

- A dial-up connection for the exchange of drawing and business data

Purchasing offices

- Central Purchasing Plettenberg

- Purchasing WTP Plettenberg

- Purchasing SPC Theley

- Purchasing Bad Emstal

![[Translate to English:] [Translate to English:] pc_unternehmen_header.jpg](/fileadmin/_processed_/6/e/csm_pc_unternehmen_header_51a49ed7a8.jpg)